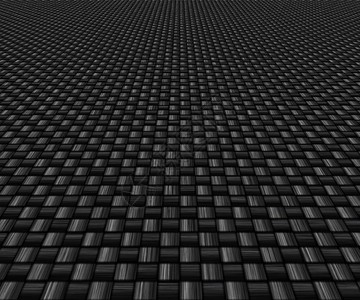

UAV and composite material

Back in 1948, aircraft were made primarily of metal alloys, which were

extremely heavy, noisy, corrosive and required extensive amounts of

maintenance making them less efficient than modern solutions for flight.

The aerospace industry has steadily been adopting composite materials

into their designs to achieve lighter solutions with the same strength

of metal alloy counterparts yet with many added benefits such as

corrosion resistance, lower required maintenance, advanced sound

attenuation (noise reduction), greater design freedom and longer life

spans. Since 1987, the use of composites in the aerospace industry has

doubled every five years to the point now where many newer aircraft are

made with more than 50% composite materials, such as the A350 XWB and

the Boeing 777X. carbon fabric,carbon plates ,honeycombed plates are lightweight ,anti erosion,sound isolation are ieal material for bulkhead of modern aviation industry